measure thickness while sanding guide|best sanding for woodworking : trade If you're looking to effectively sand a piece of wood or furniture, this guide is for you. Learn the basics, different sanding techniques, and more. Fiz uma aposta hoje (27/11/22) na opção Croácia ganhar por qualquer outro resultado, nisso o placar estava 2x1 o jogo foi passando e eu percebi que o meu cash out estava abaixando, mas estava saindo gol e a partida terminou 4x1 e pela a lógica a Croácia ganhou por outro resultado! . Para mais detalhes acesse: https://br.betano.com .

{plog:ftitle_list}

Resultado da We compared two 8-core processors: Qualcomm Snapdragon 870 (with Adreno 650 graphics) and Snapdragon 778G (Adreno 642). Here you will .

tips for sanding woodworking

windows 10 memory hard drive test

Other than using a stationary sanding machine or a belt sander, which will take a good deal of practice to learn to control, there are three methods of sanding wood: with just your hand backing the sandpaper, with a flat block backing the sandpaper and with a vibrator or . Sanding your woodworking projects can be straightforward. You just need to know a couple things to get it right. Today, I’m giving you 15 Sanding Tips to help you sand boards accurately and avoid disaster. To make thin hardwood strips for edging and Shaker-style boxes, I bandsawed stock to rough thickness and then tried to sand the pieces to final . Sanding is a crucial step in any woodworking project. By taking the time to sand the wood properly, you create a smoother and more durable surface. Just be sure to use the right sandpaper, sanding block, and technique for the .

If you're looking to effectively sand a piece of wood or furniture, this guide is for you. Learn the basics, different sanding techniques, and more.

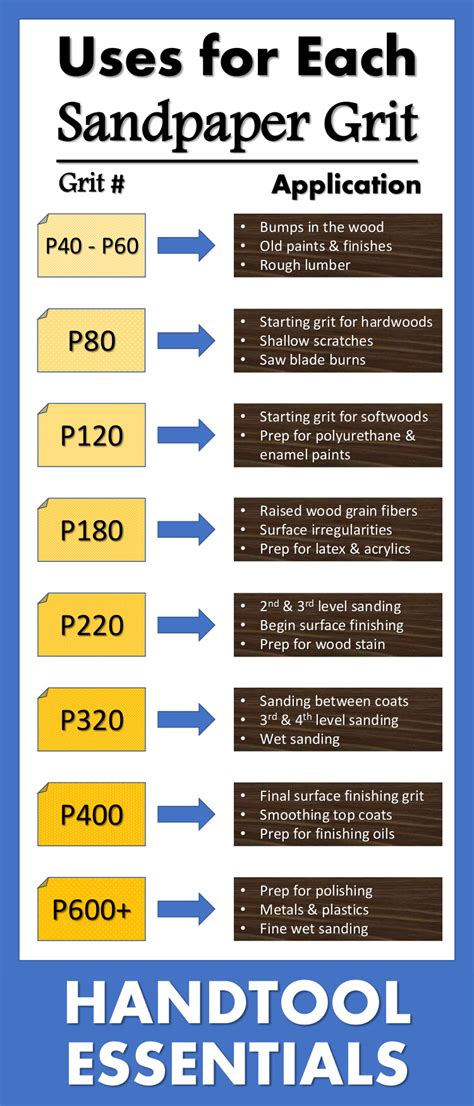

Sanders. Sanding Basics. Get the best finish by prepping the wood carefully. By. WOOD Magazine Staff. Published on August 2, 2018. Jim Heavey. There will never be a project in your shop that doesn't require sanding prior to . Sand each strip and measure the thickness using a micrometer. Add a shim between the back edge of the fence base and the wood in the miter channel. Make another sanding pass. Breaking Down Each Sandpaper Grit. Starting with the wrong sandpaper grit can add hours to your woodworking project. A grit that is too coarse may remove more material . The sizes are standardized and determined by two main methods: sieve number or micro grain. With the sieve number, grain size is determined by the number of meshes per .

Always wear protective gear, including safety glasses and a dust mask, especially when sanding materials that can produce harmful dust. Additionally, be careful not to apply too much pressure while sanding, as it could cause unnecessary damage to the surface or even cause injury. Mistakes to Avoid When Choosing and Using Sandpaper Grits

While thickness can range widely, the most common sizes you’ll find at the hardware store include 1/4 inch, 1/2 inch, and 3/4 inch plywood sheets. . A sheet that’s nominally 3/4 inch might actually measure about 23/32 inch. . The . Update 2017: New ASTM Standard D8136 For Measuring the Thickness and Variability of Plastic Film available here. This article will discuss off-line gauging and on-line gauging for plastic film, including blown film and . Loosen the tension on the sanding belt by turning the adjustment screw counterclockwise. Place the new sanding belt onto the sander and align it correctly. Tighten the tension on the sanding belt by turning the adjustment screw clockwise until the belt is snug. Check the tension of the sanding belt by pressing it with your finger.

sanding wood grades

Measure every few rounds of this. A good starting place to get to is 0.06 or maybe even 0.05mm above the blade thickness. Once you get close to the initial target (no less than 0.05mm more than the blade thickness), clean the bushing, and fully reassemble the knife. Fully tighten the pivot screw, and test for swing. THERE IS TWO MAIN WAYS TO MEASURE YOUR SANDING BELTS: 1. You can measure a brand new belt by easily first measuring the width, then laying the belt down as flat as possible without bending or creasing the belt in a way that will damage it, measuring from one end to the other, then DOUBLING the size as this is a belt and NOT a flat sheet in this . Here’s the thing. Sanding your woodworking projects can be straightforward. You just need to know a couple things to get it right. Today, I’m giving you 15 Sanding Tips to help you sand boards accurately and avoid disaster. I know. Sanding sucks.It's suitable for all types of sanding, from coarse to fine sanding. Some types of sanding paper are designed to be attached to sanding machines and come with holes which enable you to vacuum the sawdust as you go. Other types of sanding paper are available as sheets to use by hand or to wrap around a sanding block.

Prerequisite: A paint thickness gauge (aka paint depth meter) is used to measure the thickness of a vehicle’s paint job to determine whether or not a car has received paintwork after it left the factory (either due to a prior accident, paint damage, etc). A repainted panel will generate a higher reading than a panel wearing original paint.

Extra-coarse (24-, 30- and 36-grit): Generally used for preliminary hardwood floor sanding, this usually comes in belts that fit on a drum sander, or disks that fit an edger. Coarse (40-, 50- and 60-grit): Coarse grits remove a lot of material quickly, like sanding paint off wood or sanding out deep gouges. Coarse grades are available in 9- x . This process involves sanding the repaired area to achieve a level and seamless finish. Begin by using 36-grit sandpaper, which has a rough texture to help remove any excess filler and achieve a uniform surface. Using a sanding block or your hand, exert gentle pressure while sanding in a circular or back-and-forth motion.

thickness of a human hair as measured on the rotor face at the outside edge of the brake rotor — (less than .001”). Thickness Variation (TV): This is the amount by which the brake rotor’s thickness varies if you were to measure it in several (usually 4–6) different locations around the rotor with a micrometer. Thickness Variation is gener- You can also use a paint meter gauge to measure the paint thickness on a vehicle. Be aware, however, that the thickness reported by a paint meter includes the entire coating, from the primer and paint to the clear coat. Wet sanding is often used between automotive paint and finish layers. SBC-1 Spoke Gauge: The spoke gauge is used to measure the thickness of the spokes. It ensures that you select the correct size for your wheel build. Measuring devices: Having two extra spokes and two nipples can be .Assess whether hardwood floors are refinishable by checking the wood’s thickness; solid hardwood can usually be refinished 4-5 times, while engineered wood typically allows for only one sanding. Proper preparation of the space is .

Grade CAMI FEPA Description Common Uses; Extra coarse: 24, 30, 36: P12, P16, P30, P36: 530 to 1,815 micrometers: Sanding extra rough and uneven surfaces; Removing stubborn paint and varnishThis includes sanding belts, sanding discs, sanding sheets, and specialty abrasive products like knife-making kits. If you have questions or would like to place an order, please contact us by calling 844-824-1956 or filling out our contact form today.

Wood Sanding 101 - Beginners' Guide to Sanding Wood Jul 17th 2023. Blog Search. Search. Ask any woodworker or handyperson, and they'll likely tell you that sanding doesn't top their list of favorite parts of completing a project. . For sanding wood, there are also options that have vacuum holes for removal of dust while sanding. Benefits .Sandpaper grits are categorized by how coarse the abrasive material is. You will ideally start with a coarser abrasive and use progressively finer ones to achieve a smooth result. The most common grits are 60-80 (extremely coarse), 100-150 (medium grit), 180 .Measuring the speed of a drill press is essential for getting the desired results and ensuring the safety of the operator. There are various alternative methods of measuring the speed of a drill press. One such method is by using a tachometer. A tachometer is a device that measures the rotational speed of a shaft or disk. However, as any keen DIYer knows, there’s nothing quite like bringing an old piece of furniture back to life or refinishing hardwood floors and neither of these tasks (or hundreds similar) can be properly achieved without at least a smidgen of sanding. If you want to avoid the pitfalls and grab all the glory instead, read on because our complete guide to .

Nissan & Infiniti vehicles now require that you eliminate lateral run-out to less than the thickness of a human hair as measured on the rotor face at the outside edge of the brake rotor — (less than .001”). Thickness Variation (TV): This is the amount by which the brake rotor’s thickness varies if you were to measure it in several (usually Contents. 1 Key Takeaways:; 2 Importance of measuring brake rotor thickness regularly. 2.1 Evolution of rotor thickness in modern automakers; 2.2 Safety implications of worn-out or thin rotors; 3 When to check rotor thickness; 4 The process of measuring rotor thickness using a micrometer. 4.1 Multiple measurements in different spots; 4.2 Keeping a distance from . When sanding plaster surfaces a medium grit is ideal, a 60 grit paper will work well on rough or textured plaster. A fine, 120 grit paper or even extra fine grit sandpaper will be required to achieve a smooth plaster finish. Tools You Can Use for Sanding Down Surfaces. If you are sanding by hand use a cork or rubber block to wrap sandpaper around.Dry Film Thickness – Ferrous and Non-Ferrous Metallic Substrates (ASTM D7091 and SSPC-PA2) Photo 7 – Non-destructive dry film thickness gage being used to measure the thickness of the coating on hand rail. The measurement of all coats on the railing is 6.8 mils.

Fine sanding is sanding your wood finer with a #180 or #220 grit sandpaper. In most cases, sanding wood past #180 grit is rarely beneficial. The appearance of a finish, especially film-building finishes such as varnish, shellac, and lacquer, after a couple of coats will be independent of how fine you sand the wood.

Resultado da BabyPunter 1mo ago #2534884. Damn! I've seen countless headshot videos, none of them where they turned into a blood fountain like that, & only one .

measure thickness while sanding guide|best sanding for woodworking